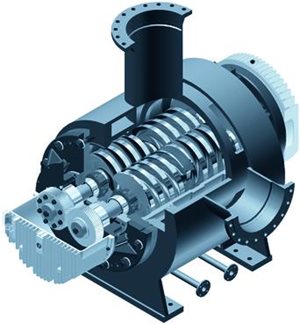

Bornemann Twin-Screw Pumps are self-priming, double ended positive displacement pumps with external timing gears and bearings. Manufactured in over 80 sizes, their design provides complete axial balancing of the rotating elements and eliminates all metal-to-metal contact within the pump.

They can handle virtually any non-homogeneous fluid, regardless of viscosity, lubricity or abrasiveness e. g. seawater, bitumen, molasses, lime, acid, caustic solution or hydrocarbon.

While pumping there is no metal-to-metal contact within the pump housing. This allows good pumping performance even with non-lubricating and corrosive and contaminated fluids.

As the pump rotates, the intermeshing of the two screws along with the pump housing form chambers. These chambers fill with the pumped fluid and move it from the suction side of the pump to the higher pressure discharge side of the pump.

The pump is designed to allow for reverse flow by simply changing the shaft direction. The suction becomes the dis-charge and vice versa, all without any modifications to the pump.